According to the British Chambers of Commerce (BCC), the UK manufacturing sector risks stagnation. This warning comes from the BCC’s Quarterly Economic Survey (QES) which saw manufacturing export sales drop to their lowest levels since 2009 in the final quarter of 2015. Rob Phillips, sales and marketing director of professional battery manufacturer Accutronics, investigates how the industry can recover.

UK manufacturing industry is bordering on stagnation

[fa icon="calendar"] Jun 6, 2016 10:20:12 AM | posted in Manufacturing industry insight

Getting a square peg into a round hole

[fa icon="calendar"] May 23, 2016 9:30:00 AM | posted in Products & Services

Have you ever watched a child puzzle over how to get the square peg in their hand into that round hole? Being a battery original equipment manufacturer (OEM) can often raise the same quandary. However, rather than simply hammering the square peg in as it is, OEM designers take the opportunity to get innovative.

Accutronics and portable electronics

[fa icon="calendar"] May 19, 2016 10:30:00 AM | posted in Insider

Building better batteries

[fa icon="calendar"] Apr 21, 2016 11:00:00 AM | posted in Products & Services

Battery specialist Accutronics has upgraded its Staffordshire test facility with a new range of specialist battery testing equipment. The new Maccor model 4200 multifunction desktop cabinet and separate floor-standing temperature chamber rigorously tests batteries for applications ranging from portable instrumentation and medical devices to robotics and defence.

Safety End Caps for Inspired Energy Batteries

[fa icon="calendar"] Apr 19, 2016 11:30:00 AM | posted in Products & Services

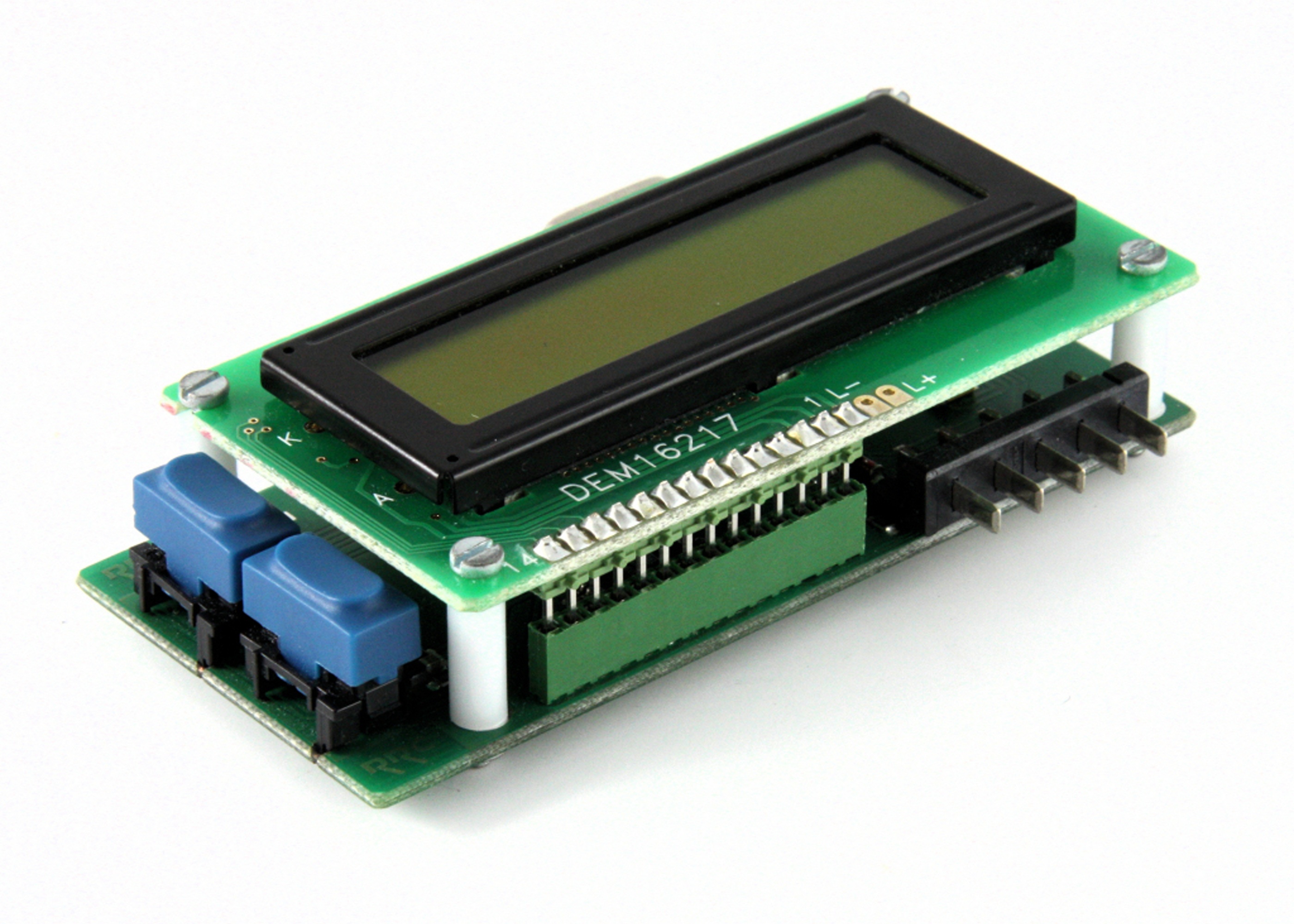

Smart Battery Gadget - 'The Data Reader'

[fa icon="calendar"] Apr 6, 2016 1:00:00 PM | posted in Products & Services

The rechargeable battery industry isn't known for its gadgets but this Smart Battery Reader is a gadget which becomes invaluable once you have one.

The internet of vulnerable things

[fa icon="calendar"] Apr 5, 2016 11:00:00 AM | posted in Cyber security

Every year in Louisville, Kentucky, hackers and security experts gather for DerbyCon. While a get-together of hackers may sound troubling on its own, what’s truly disturbing is what came out of last year’s conference. Medical cyber crime is on the rise, and there are thousands of critical medical devices which can currently be located online and hacked directly.

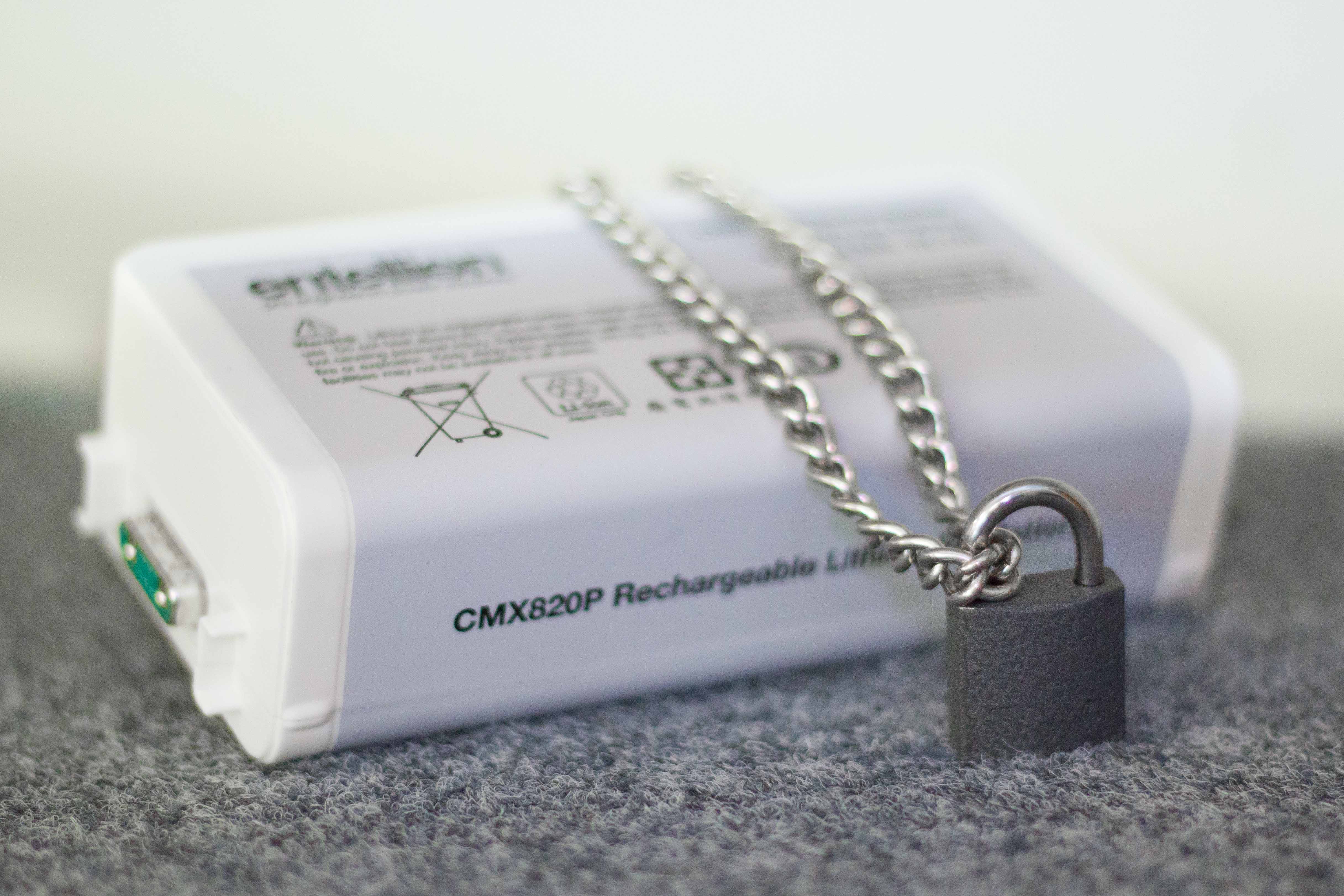

A guide to safely transporting Lithium-ion batteries

[fa icon="calendar"] Mar 24, 2016 4:00:00 PM | posted in Insider

Accutronics has released a one-page guide about the safe transportation of lithium-ion batteries. Targeted at original equipment manufacturers (OEMs) in the medical, defence and instrumentation sectors, the guide offers five quick steps to ensuring that batteries meet international standards of design, assembly and testing before being packed for shipment.

As well as new changes coming into force from 1 April in relation to the State of Charge (SoC) of batteries transported by plane, the guide also highlights IEC standards, UN testing regulations and special provisions required before batteries can be shipped by plane.

The rise in demand for smaller, more portable devices that require a lot of battery power has resulted in more compact and energy-dense batteries. Customers in industries including medical, healthcare, security, defence and instrumentation are increasingly using feature-laden devices with power hungry features including colour touchscreens, GPS antennas and Wi-Fi radios, more powerful processors and onboard storage.

It can be a challenge to navigate the maze of regulations, for example, batteries in medical applications must meet the requirements of IEC safety testing in addition to the mandatory transportation testing. With the high volume of batteries now being shipped by plane globally, it is important that businesses offering batteries for transport are aware of their responsibilities.

The WiFi wand is no magic solution

[fa icon="calendar"] Mar 17, 2016 9:00:00 AM | posted in Cyber security

Researchers at Dartmouth College in New Hampshire, USA, recently developed a small piece of hardware that enables medical devices to securely connect to WiFi networks. Due to its wand-like appearance, the system has been dubbed the magic wand of MedTech.

Unfortunately, there is little that is magical about the device. While it does address the problem the medical technology (MedTech) and healthcare sectors are facing in regards to cybercrime, there is much more that needs to be done to secure medical hardware.

Need a smart battery charger to use in your vehicle?

[fa icon="calendar"] Mar 1, 2016 2:12:15 PM | posted in Products & Services

For heavy users of batteries the need to charge them is paramount.