For large medical devices, battery power is mainly used as a backup in case of mains failure. For handheld and wearable devices however, they are the primary power supply. Any downtime could threaten the well-being of the patient, which makes the efficacy of the batteries just as vital as the monitors or sensors they might be powering.

Three common requirements that original equipment manufacturers look for in medical-grade batteries are high power capacity, small physical size and reliability. With both handheld and wearable medical devices, manufacturers aim to integrate batteries that meet these needs. But what differentiates the requirements for handheld and wearable devices?

Wearable devices

One of the most common types of wearable device in medical technology is remote patient monitoring equipment. Often worn around the neck or arm and taken with the patient wherever they go, these devices transmit vital data about the patient to the doctor in real-time. As the patient must wear the device for a prolonged period, it is important that they are as non-obstructive to the patient as possible. Non-rechargeable (primary) batteries may be better suited than rechargeable (secondary) ones for this application, due to their smaller size for a given amount of energy.

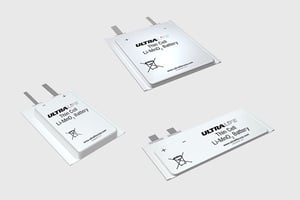

For example, Ultralife Thin Cells® measure as little as 1.1mm in depth, which is compact enough for embedding into wearable devices. Yet these cells also boast a high energy density of around 500Wh/l and 400Wh/Kg compared to just 300Wh/l and 260Wh/kg for the best lithium coin cells. They pack a lot of energy into the smallest footprint available, with no compromise to efficacy or safety. This gives designers the freedom of putting together a compact, light and ergonomic device.

For example, Ultralife Thin Cells® measure as little as 1.1mm in depth, which is compact enough for embedding into wearable devices. Yet these cells also boast a high energy density of around 500Wh/l and 400Wh/Kg compared to just 300Wh/l and 260Wh/kg for the best lithium coin cells. They pack a lot of energy into the smallest footprint available, with no compromise to efficacy or safety. This gives designers the freedom of putting together a compact, light and ergonomic device.

Another reason why primary batteries are ideal is that removing a wearable device from the patient to charge the battery could result in gaps in the data, which would prevent the device from fulfilling its function. This also applies to other wearable medical devices like hearing aids, where it would be impractical for an individual with hearing impairments to remove the batteries for a long period to charge them.

Handheld devices

Both wearable and handheld devices share a common link — size matters. Where wearable devices need to fit around a neck or arm, handheld medical devices need to be small enough to fit comfortably in the user’s hands for an extended period.

Temperature checkers are a common example of a handheld medical device. Unlike wearables, handheld devices are unlikely to be in constant use, meaning that the batteries have time to recharge. Rechargeable batteries tend to offer a longer service life than non-rechargeables, offering better value for hospitals with budget constraints.

Although handheld equipment may incorporate secondary over primary batteries, the need for reliability and high-power capacity is the same. The temperature checker, just like the wearable remote patient monitoring devices, is relaying vital patient data to the hospital.

Although handheld equipment may incorporate secondary over primary batteries, the need for reliability and high-power capacity is the same. The temperature checker, just like the wearable remote patient monitoring devices, is relaying vital patient data to the hospital.

Accutronics’ range of credit card lithium cell batteries are ideal for this application as they are both compact and high in performance. At just 9.1mm, the CC3800 offers a large storage capacity of 3800mAh.

As you can see, although both handheld and wearable medical devices strive to meet high power capacity, small physical size and reliability requirements; the type of battery can differ based on the specific application. Speaking to a professional battery manufacturer, such as Ultralife Corporation or Accutronics Ltd, at the design stage can ensure that medical device manufacturers get the battery that is best suited for their device.