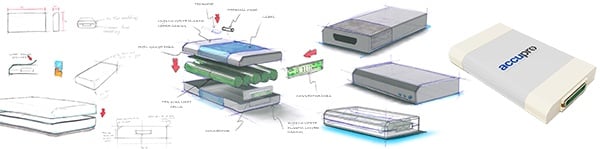

Accutronics develops batteries for professional markets where the requirements for size, weight and environmental performance are very high on the list of customer needs. As mechanical engineering manager David Asplin works closely with our clients throughout the custom battery design process.

Asplin specialises in the mechanical aspect of the design and prototyping of custom batteries at Accutronics. The first step in this process is to discuss every aspect of the application with the customer and his objective is to incorporate all requirements into a battery that is both strong and durable whilst remaining light and compact.

Asplin specialises in the mechanical aspect of the design and prototyping of custom batteries at Accutronics. The first step in this process is to discuss every aspect of the application with the customer and his objective is to incorporate all requirements into a battery that is both strong and durable whilst remaining light and compact.

Accutronics takes full advantage of the latest digital prototyping techniques to get the design to market quickly. We perform finite element analysis of the CAD models and employ 3D printing technologies such as stereo lithography apparatus and selective laser sintering to generate physical prototypes. Mould flow simulation is used to test and validate the injection moulding design prior to tooling.

When compared to those who select an off the shelf solution, customers that choose a custom battery have the benefit of an optimal solution where every facet of the design can be tailored to meet their device and market requirements.

“Well designed and efficiently manufactured-to-order batteries will guarantee that you get exactly what you want, with minimal compromise on performance, shape, colour or other physical qualities,” explains Asplin. “Although the initial costs can be higher than for an off-the-shelf solution, custom design allows the Accutronics customer to brand the product in whatever way they want and guarantee its performance. I can say this with confidence as we also offer a range of standard smart batteries for markets that don’t warrant the investment in a custom smart battery solution,” he continued.

“Well designed and efficiently manufactured-to-order batteries will guarantee that you get exactly what you want, with minimal compromise on performance, shape, colour or other physical qualities,” explains Asplin. “Although the initial costs can be higher than for an off-the-shelf solution, custom design allows the Accutronics customer to brand the product in whatever way they want and guarantee its performance. I can say this with confidence as we also offer a range of standard smart batteries for markets that don’t warrant the investment in a custom smart battery solution,” he continued.

“Furthermore, in some industry sectors, such as medical and healthcare for instance, a bespoke battery design is often the only viable option. Innovative mechanical engineering is the only way of ensuring the product can withstand chemical corrosive cleaning, and unusually high levels of user abuse”, concluded Asplin.

If you are interested in learning more about our Accupro custom battery design and manufacturing service, please contact our Sales team on+44 (0)1782 566622 to discuss your requirements or